3367 publications

The Global Economy: Caught in the Storm / Politique étrangère, Vol. 91, No. 1, 2026

The global economy has become the primary arena for the clash of power ambitions in a world where understanding, coordination, and concerted multilateralism seem to have been permanently marginalized. In this fragmented landscape, how will American and Chinese strategies interact? Will the European Union manage to break out of its decades-old framework in order to face new competition? And will it be able, like others, to integrate the announced shift from a production economy to a digital, information economy? And what role will financial institutions, and central banks in particular, play in this transitioning international economy?

Official Development Assistance in the Age of Deglobalization

Official development assistance has collapsed since 2023, both in Europe and in the United States. This decline has affected both developing and industrialized countries. Under fire in the Global North and South, the goals and methods of development assistance must be redefined if it is to adapt to an international landscape in which the principal actors—the United States, the European Union, China, the Arab countries—are adopting new stances.

Digital Revolution, Economic Upheaval

The digital revolution is profoundly shaking up the economy, with the impact felt well beyond the digital sector itself. Indeed, it is transforming the very concept of value creation. Artificial intelligence represents a new phase that requires a colossal investment in physical infrastructure like data centers. Europe failed to grasp the scale of these changes in time, but it does have certain advantages.

The 2026 State Elections in Baden-Württemberg: First Test For Chancellor Merz's Federal Government?

The state election in Baden-Wuerttemberg in March 2026 will be the first major test of public opinion for Chancellor Friedrich Merz's federal government. At the same time, Baden-Wuerttemberg is one of the federal states that—as an important location for the German automotive industry and its suppliers—is particularly affected by the transformation policy driven by climate change and the international conflict constellation.

Financial Tools for Boosting Resilience of CRM Value Chains and Strategic Stockpiling

Critical Raw Material (CRM) value chains are more vulnerable than ever and entire vital industries in Europe are now at risk if supplies are not secured through strategic and urgent actions, given mounting geopolitical confrontation, resource nationalism, growing demand and limited supply increase.

Bundeswehr: From Zeitenwende (historic turning point) to Epochenbruch (epochal shift)

The Zeitenwende (historic turning point) announced by Olaf Scholz on February 27, 2022, is shifting into high gear. Financially supported by the March 2025 reform of Germany’s “debt break” and backed by a broad political and societal consensus to strengthen and modernize the Bundeswehr, Germany's military capabilities are set to rapidly increase over the coming years. Expected to assume a central role in the defense of the European continent in the context of changing transatlantic relations, Berlin’s military-political position on the continent is being radically transformed.

Russia, the Palestinians and Gaza: Adjustments after October 7th

The Soviet Union (USSR), and subsequently the Russian Federation as its internationally recognized legal successor, has consistently sought to play a visible role in efforts to resolve the Israeli-Palestinian conflict.

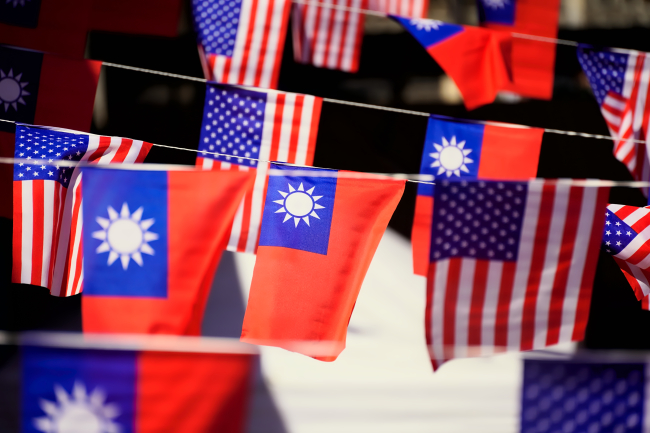

The U.S. Policy Toward Taiwan Beyond Donald Trump: Mapping the American Stakeholders of U.S.-Taiwan Relations

Donald Trump’s return to the White House reintroduced acute uncertainty into the security commitment of the United States (U.S.) to Taiwan. Unlike President Joe Biden, who repeatedly stated the determination to defend Taiwan, President Trump refrains from commenting on the hypothetical U.S. response in the context of a cross-Strait crisis.